Based on the concept of full integration and automation, the DCS system is designed according to the execution layer, control layer, operation layer, and information layer. The DCS system serves as the control core, and various on-site instruments are unified and integrated under the system platform through relevant communication interfaces, achieving lossless data collection and transmission. Instrument calibration settings are completed with one click, and information interfaces are reserved upwards, preparing for future information upgrades of the enterprise.

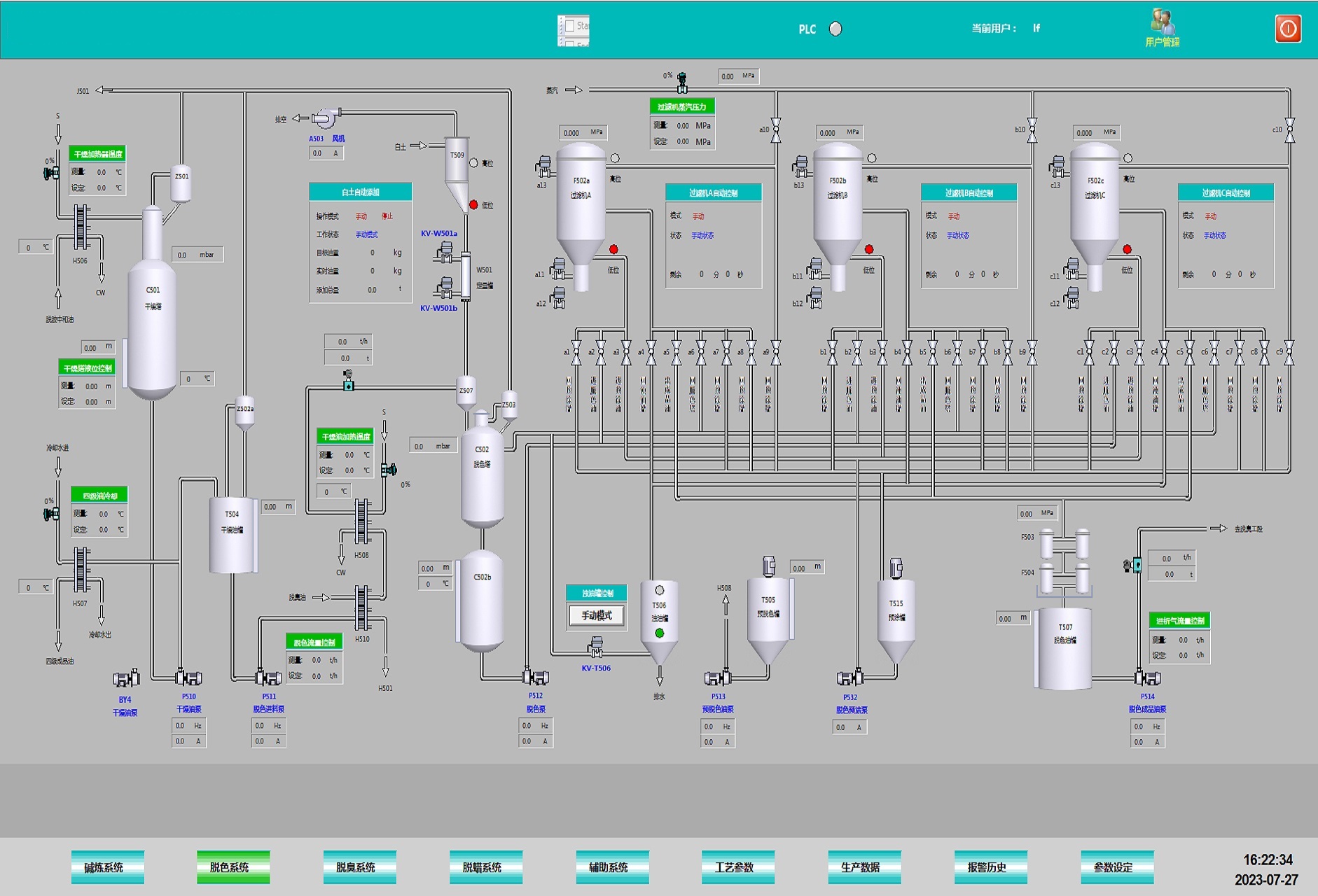

This example is applied to a central enterprise in Shaanxi, mainly achieving online alkali preparation, online water addition, and centrifuge signal integration and integration into the system. The workshop electricity meter, frequency converter, etc. are divided into several groups and connected to the system through MODBUS network. Various flow meters are connected to the system through the 485 RTU network, and there are two operation terminals configured on site to facilitate on-site operators to set and modify parameters, The central control room is equipped with a server for data collection, report processing, etc. Two operator stations are configured to operate the two main workshops respectively. In addition, two large screen displays are configured to visually display real-time process production processes.

Since the project was put into operation, it has been running stably and reliably, with accurate and effective control, and a simple and friendly operating interface, which has won high praise from users.