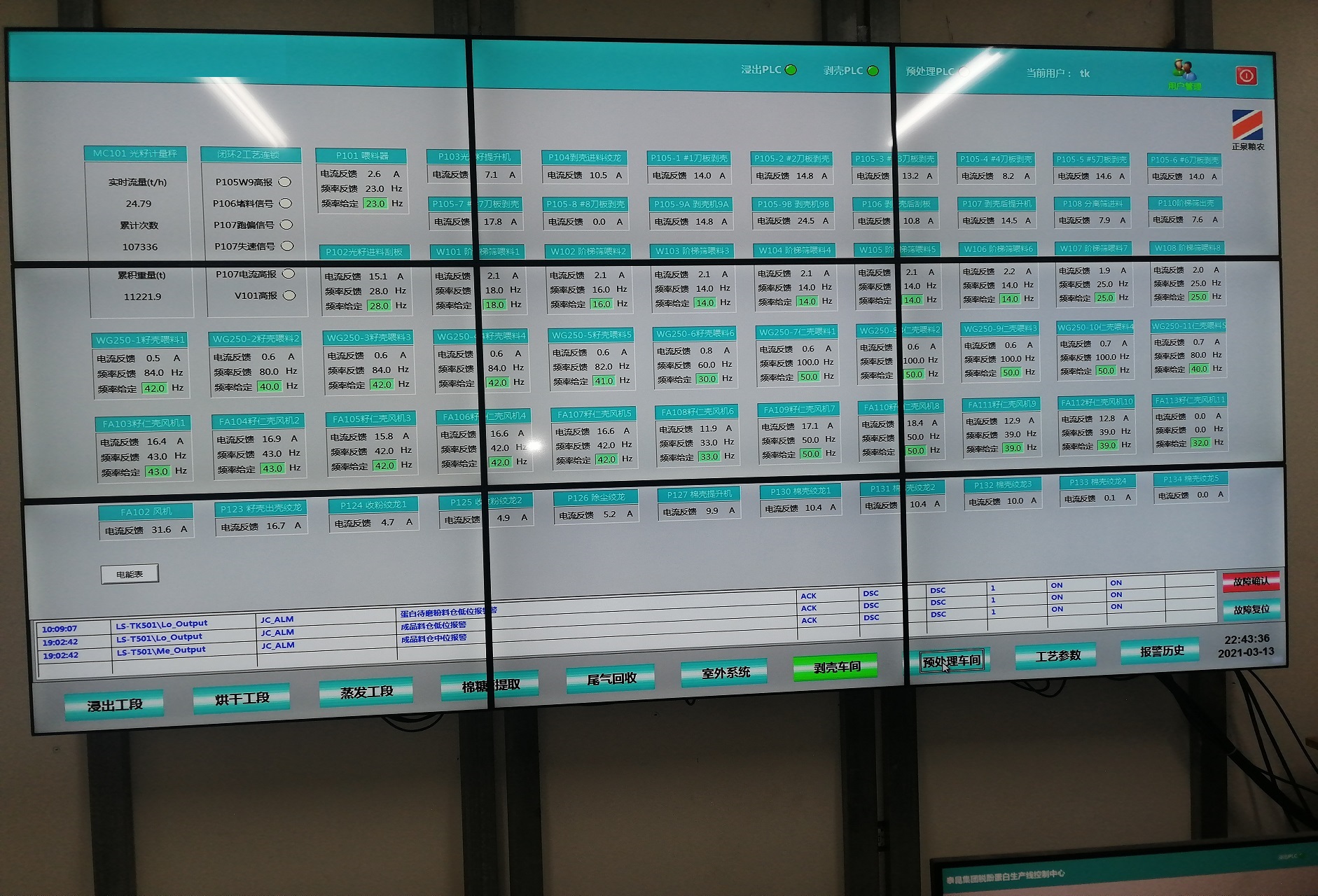

This platform connects process data with information technology data, achieving a deep integration of automation and information technology in a true sense. While controlling and monitoring equipment in the factory area, it can understand relevant equipment and management information data, promote the execution efficiency of the control and monitoring center, and improve the ability of dispatch and command to make quick decisions.

The monitoring platform can complete functions such as data analysis, processing, display, and reporting. Through the stored historical data, it can analyze, query, and count the equipment operation status of each subsystem. More importantly, the monitoring platform can achieve data classification and sharing, and provide a basis for leadership decision-making through effective management system modules. The management system modules are configured and used according to actual needs. The monitoring platform should be comprehensively configured from various perspectives such as safety, production, and management of the entire factory system, so that the subsystem data accessed by the integrated automation system can be more fully utilized and better provide scientific management basis for the factory.

The example of this project is a group company in Shaanxi, which has cleared the data exchange barriers of various equipment and ensured stable data integration into the comprehensive automatic information system.